|

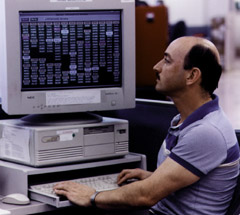

It takes more than scheduling to keep trains running. In a country

as large as Canada, railway lines employ an army of technologists

to ensure that equipment is operating safely and that the communications

network is not only constant, but efficient. Jim works as a Signal

and Communications Technologist for CN Rail. Currently, his primary

responsibility is overseeing the thermal imaging system used for

defect detection of rolling stock in Western Canada. If the axle

bearings overheat on any train in Western Canada, the office receives

an automatic warning. A train with a hot bearing - called a "hot

box" - is inspected after being stopped, either by the field equipment

or by contact from the office.

Jim's main

function is to ensure reliability in the system through monitoring

the office statistics of the field equipment's performance. Jim

also maintains detailed communications plans and records on the

computer. He is continually busy with developing and testing improvements

to the system's performance.

There are

duty rotations with his fellow technicians every couple of years.

Alternate possible assignments last approximately one to two years,

and may be in the areas of Data Communications (WAN/LAN Networks

over Fiber/MUX/Satellite), Signal Systems, and Radio Communications.

A technologist may also be assigned to the Call Desk where outages

are logged and routed to expedite restoration, or to a special

project or a specific system.

|